VOLKMANN supplies the optimum solution

Powder handling and material conveying – for powders, granulates and lumpy bulk materials – we can supply you with the optimum solution. And we also develop customised solutions and systems for our customers.

Vacuum conveying is one of our central technologies: the transport of powders, granulates, and bulk materials through pipelines and hoses from A to B. We have supplied numerous systems for the chemical, food, pharmaceutical, metal powder, and battery raw materials industries, among others.

Vacuum conveying is suitable for short distances of less than 1 meter as well as for distances of up to 100 meters. Conveying capacities from 10 kg up to 10 tons / hour can be accomplished.

We offer the right stations for handling and emptying transport containers: for drums, sacks, big bags, and IBC containers. With our dosing technology in combination with weigh cells, the material to be conveyed can be fed into a process in the exact quantity.

We are the ATEX experts in vacuum conveying. Our containment solutions offer optimum protection for personnel in the presence of hazardous dusts. For applications in the pharmaceutical industry, we develop systems in hygienic design and with WIP/CIP/SIP.

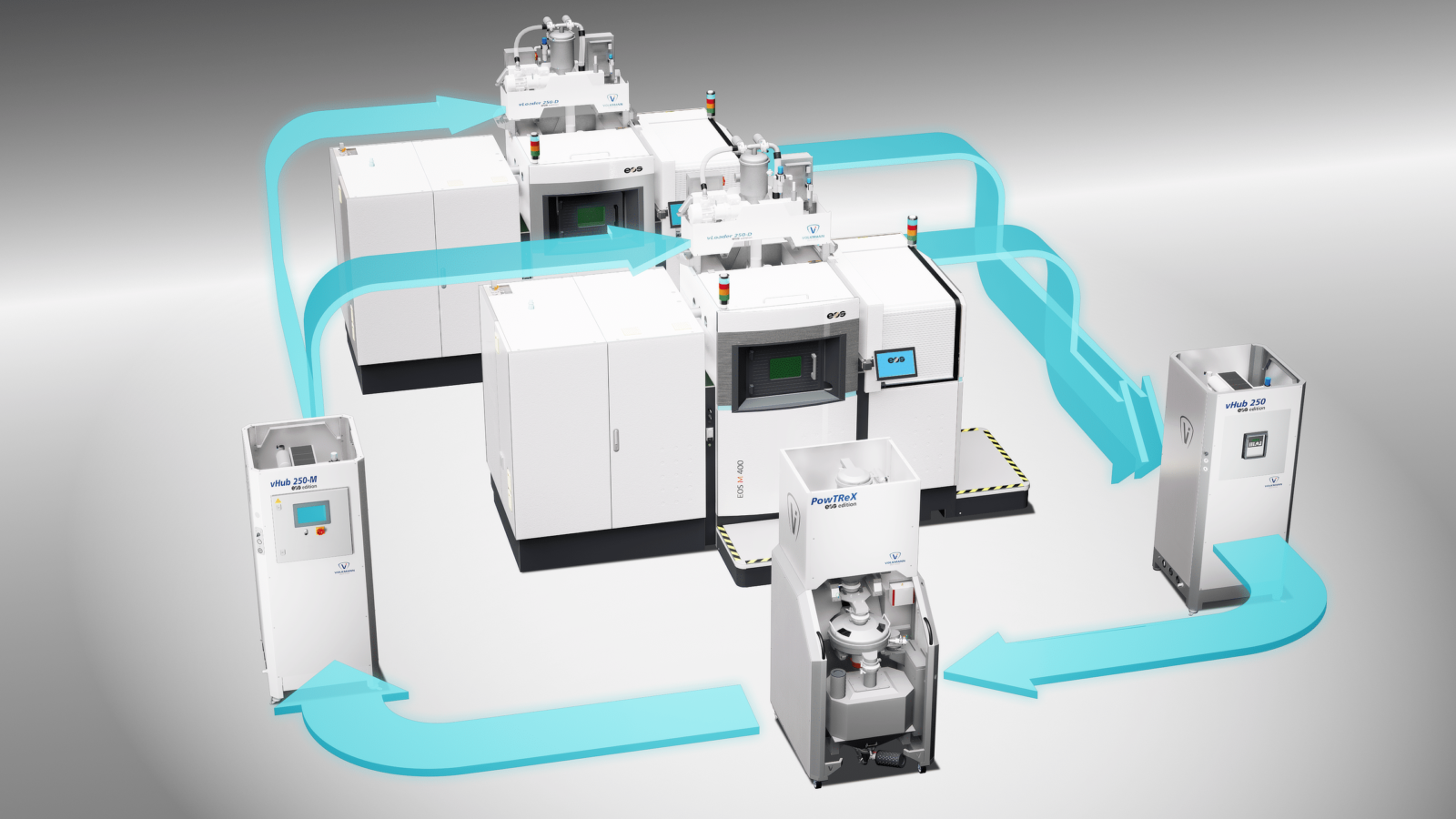

In additive manufacturing or industrial 3D printing, we are a leading supplier for the handling of metal powders and for the recycling and reprocessing of used powders.