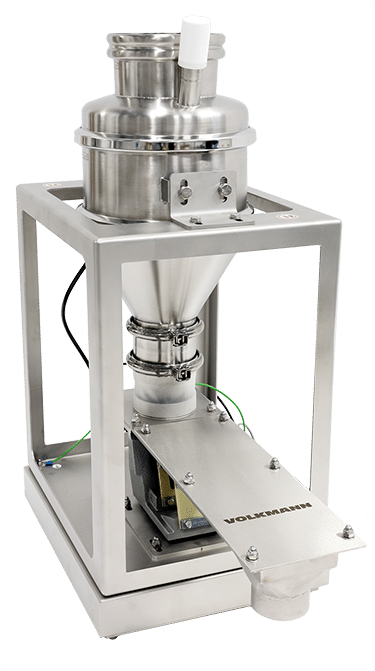

Volkmann vibrating feeder is suitable for a wide range of applications. It is ideal when automating a feeding process in combination with a vacuum conveyor and a complete with a buffer module and level probe.

Depending on the application you can use an open vibrating feeder or a closed hygienic dosing tube. Both variations are easy to clean.

Together with a vacuum conveyor and a material buffer it is possible to offer different types of weighing. For example, negative weighing or rather dosing with a vibrating feeder can achieve a batch accuracy of down to 1 g per cycle depending on the material.

It is possible to convert a discontinuous material transfer process into a continuous feeder with rates up to 1000 kg per hour.

Characteristics:

– Continuous material feed

– Accuracy down to 1 g

(depending on the material)

– More effective and gentle operation

– Easy to clean

– For use in Ex-Zones

– Low-wear

– Stainless steel AISI 304 or AISI 316

(product contacted parts)

Variations:

– Open/ closed U-profile dosing tray

– Closed pipe-profile dosing tube

– Clamp connections at the inlet and outlet

– Length and width of the dosing tube and

tray are variable

Options:

– Weighing module

– Dustfree design

– Integrate with sieving

– Quick change sieve insert

Do you find the application interesting and would you like to find out more about the topic or do you have a specific task?

Our application experts will be happy to help you Contact