Efficient, clean and safe handling of powders, granulates and bulk materials

With our products and solutions, you can handle your powder, granulate or bulk material efficiently, cleanly and safely in your production. The reliable transport of the material ensures a safe supply to your production facilities.

Our systems cover a wide range of powder handling and conveying requirements:

- low-dust or dust-free feeding of the powder, e.g. from a transport container, container, bag or bin

- gentle handling and conveying of the product

- protection of personnel and the environment from dust

- protection of the powder or material from contamination from the environment

- safe handling of dust-explosive powders and dusts

- safe handling of powders in an Ex zone

- transport of the product even over long distances and height differences

- easy integration into a production system

- easy cleaning

- low investment costs and favourable operating costs

Typical applications are the feeding of powders into a mixer or a reactor.

We offer suitable product feeding stations for feeding bulk material, e.g. from a container, big bag, drum or bags.

Powder handling with vacuum conveying can be easily customised to meet specific requirements. We develop and manufacture the perfect solution for you. We will advise you, test the solution in our technical centre and develop and manufacture the optimum system for you.

Vacuum conveyor systems are proven all-rounders for clean and safe bulk material handling. Powder, dust, granulates and small parts can also be conveyed over longer distances.

Product Loading Stations: From a sack, pack, big bag, or container: the right product feeding station enables clean emptying and feeding into a conveyor system.

Weighing and Dosing Systems: By means of load cells, vacuum conveyors can be filled precisely, and emptying from containers can be controlled accurately. Dosing chutes enable a continuous flow of material.

Hoists for Vacuum Conveyors: A lifting column can be used to efficiently dock and undock vacuum conveyors on machines and containers. In addition to stationary lifting and swivel columns, mobile lifting columns are also available.

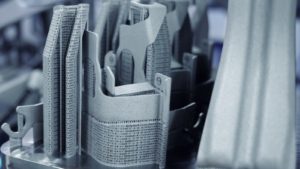

Additive Manufacturing / 3D-Printing: Systems for handling metal powders in the pre- and post-processing of 3D printing, for unpacking the build frame and build job, and for recycling the used metal powder.

Customised systems and solutions: Tailor-made systems for the optimal solution of your task – whether as an adaptation of our standard programme or as a completely new design.

MULTIJECTOR® Vacuum Pumps: Small, but powerful! Due to numerous advantages, these pumps have found a permanent place in many industrial applications.