Containment for product loading

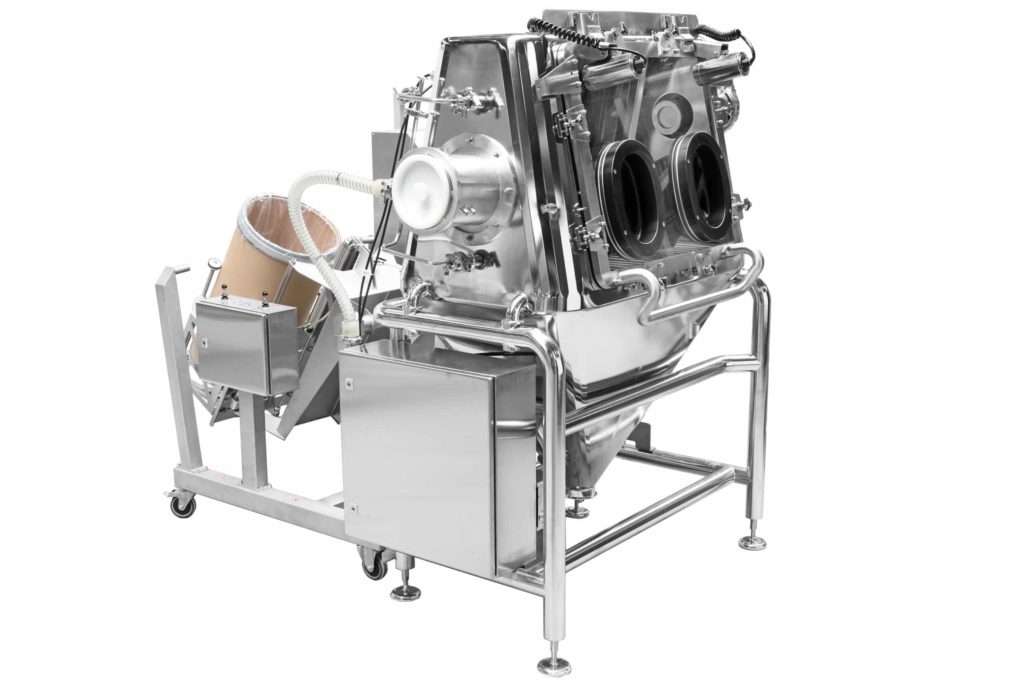

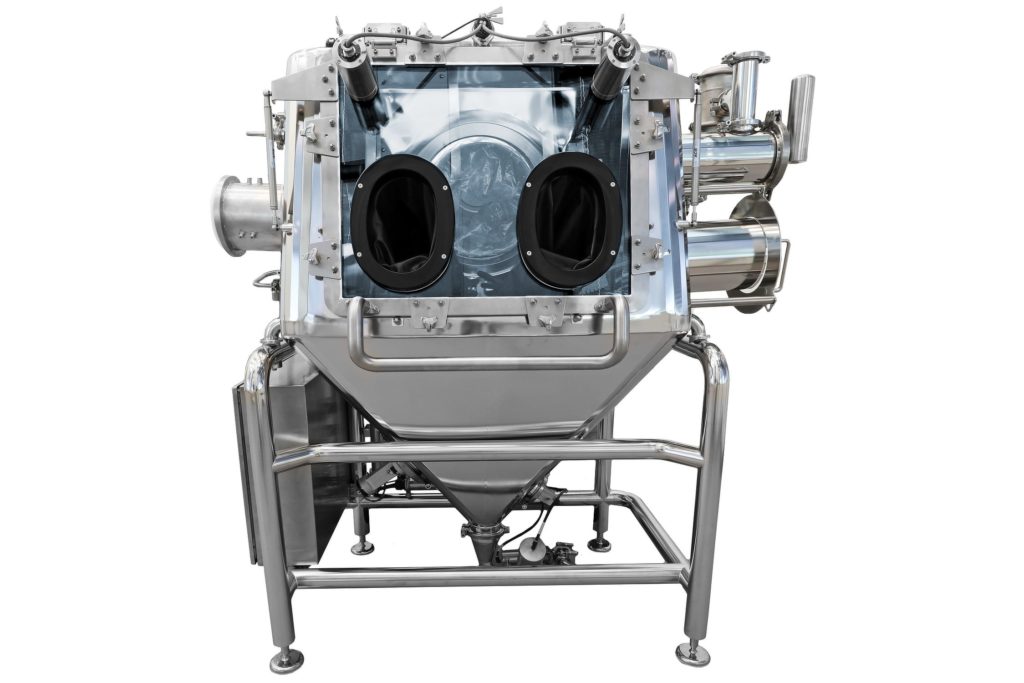

With certain applications, where highly potent or toxic materials need to be added into a process it requires dust free and contained powder unloading solutions. Volkmann’s contained Rip-and-Tip unloading station allows the opening and emptying of bulk materials from bags, boxes and other small containers completely dust and contamination free. Therefore, critical powder handling processes, that involve toxic or dangerous powders, become safe.

Functionality:

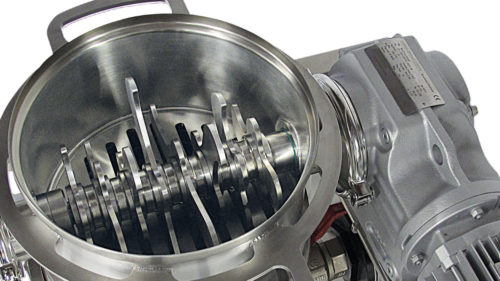

The modular design of the product feeding station, RNT-CON, enables a flexible solution with various functional units and options to suit the installation requirements. Bags or containers can be fed semi-automatically into the isolator via a roller conveyor (loading through an optional dust lock). After this dust lock, they enter the negative pressure unloading chamber. Inside the glove box isolator, they are opened manually and discharged into the feeding hopper for transfer by the vacuum conveyor. Optional Lump breakers/crushers and material agitators are available. If required, the closed station can be flushed from within using a hand washing gun or with an integrated WIP/CIP/SIP system.

Options:

- Flushing connection with washing-gun or spray balls

- Continuous Multijector de-dusting and filtration, alternatively prepared for on-site central extraction

- Door lock, operated by foot pedal

- Inlet tunnel, with the option to include a dust lock with separate dust extraction

- Dust protection, with the option to add a second pneumatic door lock

- Roller Conveyor for bags, with the option to add bag separation, vacuum lifting hoist and extended buffer zone

- Material discharge with lump breaker, with connection for vacuum conveying

- Modular connection to bring out the emptied bags, either with bag compactor, endless liner etc.