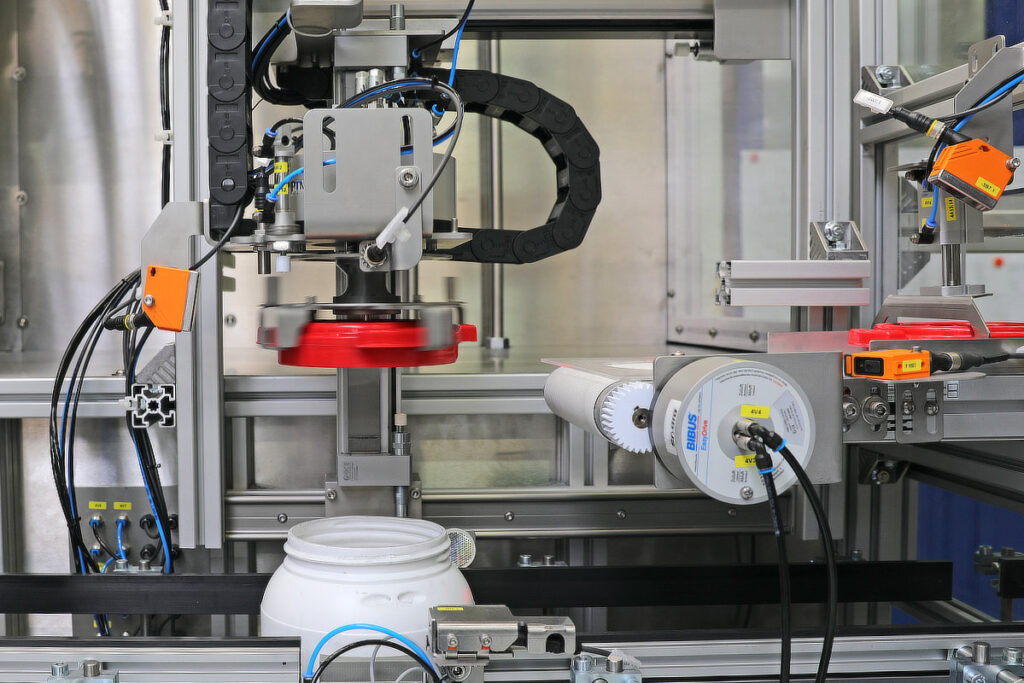

Metal Powder Filling Line

Bins, bottles or drums used for distribution of metal powder are filled and sealed safely and accurately by weight on our customizable automated filling lines. Every filling line features an integrated VOLKMANN vacuum conveying system for safe and reliable powder feed into the system.

![metal powder filling line (1500x1000px) [DE] Beispiel einer Metallpulver-Abfüllanlage, die für die Befüllung von CurTec-Behältern ausgelegt ist. Inertgas-Spülstation (links), Metallpulver-Abfüllstation (Mitte) und Deckelverschließstation (rechts).](https://volkmann.info/wp-content/uploads/metal-powder-filling-line-1500x1000px.jpg)

Enclosure automated inlet door

Container inert gas flushing

Filling station incl. container weighing

Lid closing with adjustable torque

Enclosure automated outlet door

Magazine and feeder for screw lids

Powder transfer vacuum conveyor

MULTIJECTOR® vacuum pump and HEPA filter

In our filling lines, we have combined VOLKMANN’S expertise in the areas of powder handling and conveying with mechatronics, automation and special purpose machinery construction. This provides the user with a single-source, integrated and customizable solution to exactly fit the customer’s special requirements.

Whether your containers are round or square, we offer an optimized filling line to suit the shape and size of your container including systems for processing CurTec® wide neck drums and aluminium bottles.

Filling lines can be custom-designed to fit factory floor layouts, to interface with powder production lines and various powder supply methods, and for integration with production and plant monitoring systems.

The complete filling line and integrated powder transfer system is suitable for all common metal powders.

System throughput when filling 10 kg of stainless steel powder per container is 30 containers per hour, with a filling accuracy of ± 25 grams. Filling throughput may vary based on powder type, bulk density, and other factors.

The filling line control system can be configured to communicate and exchange data with external systems.

Powder supply by means of vacuum conveying

Metal powder is transferred into the filling line with an integrated VOLKMANN vacuum conveyor. The filing line can be connected to an IBC container or other types of manual or automatic product supply. The conveying distance between the product supply connection point and the filling line can be as long as 30 meters (overall length).

As an option, metal powder can also be conveyed using inert gas such as argon or nitrogen.

Vacuum conveying is an established, proven method of safely handling and transferring metal powders and is particularly well-suited for containment of dust-explosive powders and dusts. Hundreds of VOLKMANN vacuum conveying systems are in use in additive manufacturing and metal powder applications, and several leading 3D printer manufacturers purchase these systems from us.

The integrated VOLKMANN vacuum conveyor also serves as an intermediate buffer from which the metal powder is dosed into the container via a cone valve and/or a dosing chute.

Internal components can be easily accessed and cleaned in case of product changes.

Optionally, the powder can also be dried before filling by integrating a VOLKMANN vDryer (vacuum drying) module.

Filling process steps

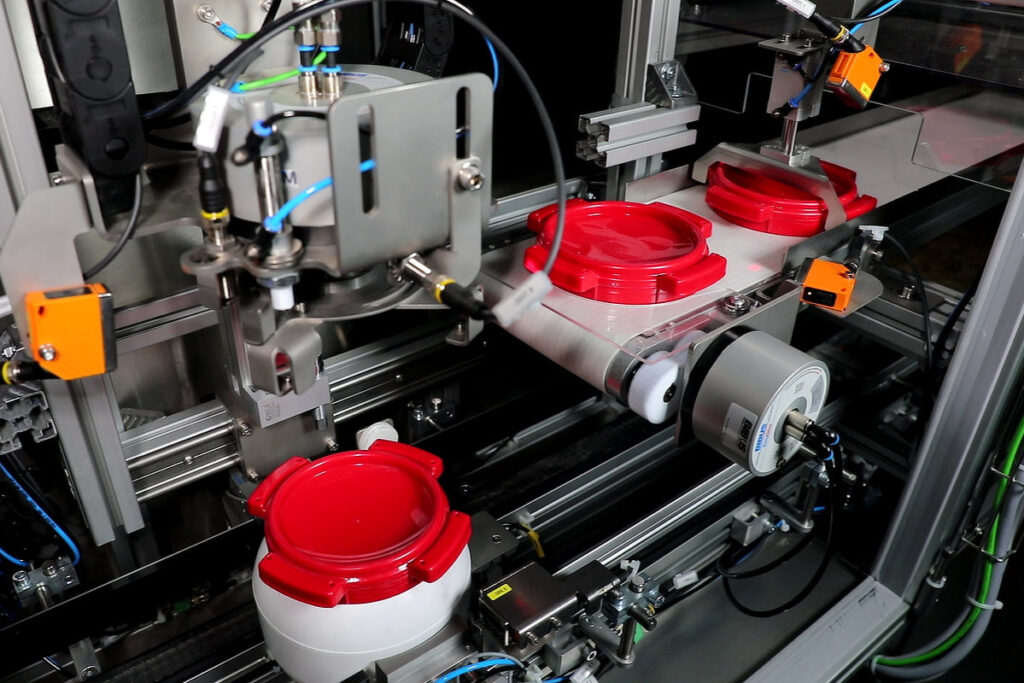

The modular concept allows the system to be configured with any combination of stations as required for the specific application:

Automated inlet door (optional): The sliding door separates the filling system from the upstream process area.

Lid unscrewing (optional): Removal of container lids if the containers are already sealed on delivery. The lids can be collected or transferred directly to the lid closing station.

Container inert gas flushing (optional): The containers are purged with an inert gas (e.g. argon or nitrogen), either before and/or after filling with metal powder.

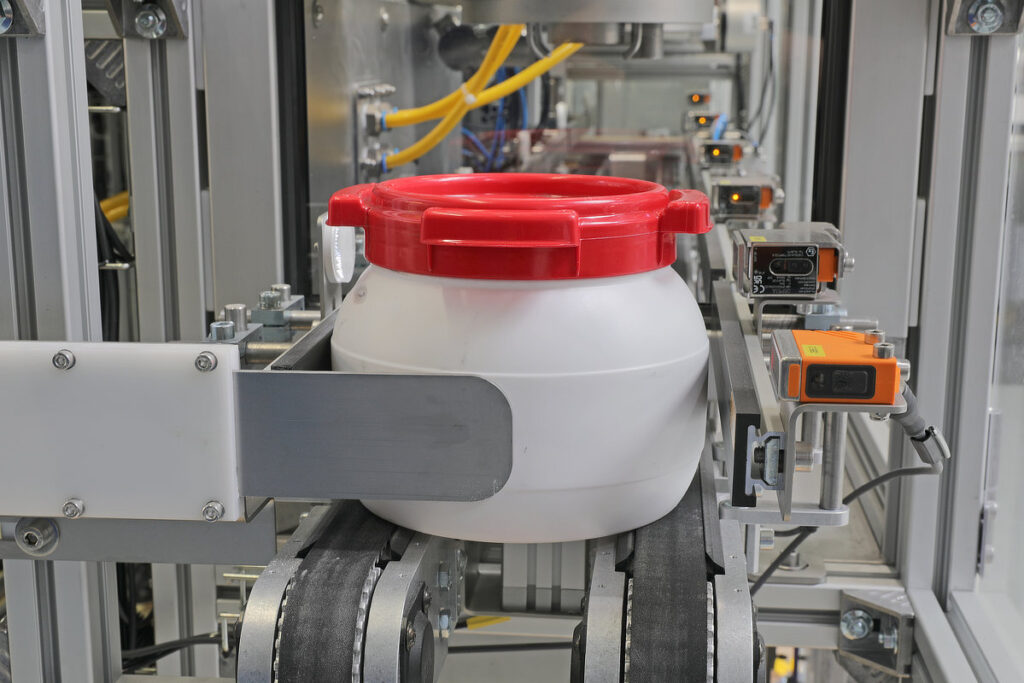

Filling with metal powder: The containers are weighed empty (tare weight) and are filled to the desired gross weight setpoint. Metal powder dust is removed via suction during the filling process.

Addition of silica bags (optional): Bagged drying agents (e.g. silica bags) are added to the container before closing.

Lid closing: The container lids are automatically dispensed from a feeder and screwed onto the containers. The closing torque is adjustable.

Labeling (optional): Application of a label on the container.

Automated outlet door (optional): The sliding door separates the filling system from the downstream process area.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information