Continuous Vacuum Conveyors CC

CC Vacuum Conveyors provide continuous aspiration and material flow, both at the material pickup and the discharge locations.

CC Vacuum Conveyors provide continuous aspiration and material flow, both at the material pickup and the discharge locations.

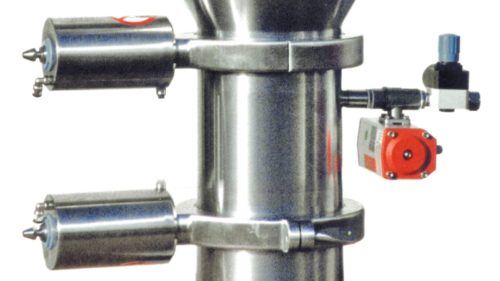

Inside the Vacuum Conveyor a Volkmann vacuum pump/filter combination is operating continuously for constant aspiration and vacuum transport. The individual pump/filter combinations are switched off, in sequence, to allow for reverse jet filter cleaning, this is while the others are still operating making sure that the constant transfer of material is possible.

The CC separator is equipped with a Volkmann designed and produced rotary valve (ATEX approved). The transported material can be conveyed, then separated and discharged from the separator/conveyor with almost no delay due to the ingenious design of the CC Vacuum Conveyor and its airflow. The amount of remaining material is limited, with adhesive material a pneumatic piston vibrator is used for further reduction of material which might accumulate on surfaces inside the separator.

The CC Conveyor and all its parts including the rotary valve can be dismantled easily by hand. All product contact parts are of a hygienic design and easy to clean (all stainless steel 316L or FDA-approved materials).

Separator diameters of CC Vacuum Conveyors available from 200 up to 350 mm, with rotary valves diam. 100 or 150 mm. Conveying rate 1 – 500 kg/h