Conveying, weighing and dosing powder

The handling and vacuum conveying of powder or bulk materials can be supplemented with dosing or weighing processes. This enables multiple process steps to be combined and automated. Powder is handled safely and cleanly within a closed system, protecting personnel and the environment.

In many processes, the recipe will stipulate that a specified weight of powder or bulk material must be fed into a system (e.g. a mixer). Another requirement may be that this feed is continuous and uniform over time; for example, this allows the material to mix more easily with other materials. Our range of products for combining material transfer with weighing or dosing offers numerous possible solutions that can be adapted to our customers’ individual needs.

Weighing and dosing can also be combined with automated vacuum conveying. This reduces the risk of product contamination and protects personnel from dust.

Volkmann solutions

In our systems, we often use standardised and proven components for dosing and weighing:

Continuous and controlled material feed

This section presents technologies that can be used to continuously feed powder or bulk materials into a downstream station. One example is vacuum conveying, which involves continuously discharging product into a downstream station, such as a mixer. However, since vacuum conveying operates with alternating conveying and emptying cycles, material discharge is intermittent. With the aid of a downstream buffer container and a vibratory conveyor, this can be converted into continuous discharge.

Another application is the continuous feeding of material from a container, hopper or silo. Without the necessary adjustments, the product would flow quickly and in concentrated form from the container into the downstream station once the valve is opened. However, by using additional components, the product feed can be stretched out over time to create a continuous flow.

Various components can be used to control material flow within a plant or machine.

A linear vibratory conveyor transports and doses powder or bulk materials via a horizontal, vibrating dosing chute. Material transport can be switched on and off at any time and the quantity transported can be adjusted continuously via the amplitude of the vibration. Vibratory conveyors are also ideal for use in conjunction with weighing systems.

A rotary valve is ideal for coarser dosing of conveyed material. Although the material feed can be spread over a longer period of time, the conveying flow is only continuous to a limited extent. One advantage is that the process areas are separated from each other by the rotary valve. This means that a pressure change in one area cannot affect the other area.

A cone valve can be used for the gravimetric emptying of a container or vacuum conveyor. The valve responds quickly to pneumatic control and can also be closed whilst the product is flowing. By timing the opening and closing of the valve, the discharge of material can be spread out, with only small quantities being fed in at a time. For many applications, this form of dosing is sufficiently accurate.

Weighing the product

Modern load cells can accurately weigh a plant component and its contents to within a few grams. The difference between the tare weight and the net weight gives the weight of the powder or bulk material contained within.

One simple application is determining the weight of powder or bulk material in a container, mixer, or vacuum conveyor.

Many users are interested in the combination of weighing and dosing. The weight is determined several times per second and this information is used by the PLC to control material conveyance and dosing. Conveyance is throttled down well before the target weight is reached and stopped at the right moment.

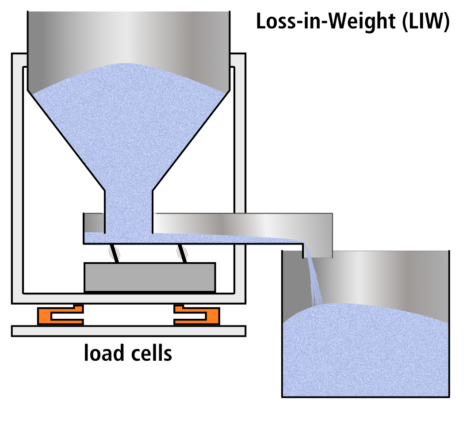

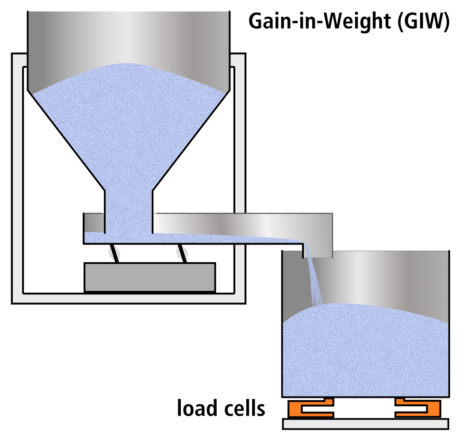

When weighing products, there are two main methods: the loss-in-weight (LIW) method and the gain-in-weight (GIW) method. The LIW method is also known as negative weighing, while the GIW method is known as positive weighing.

To illustrate this, consider the task of partially emptying a container of powder into a mixer. It is also required to determine the weight of the powder transferred from the container to the mixer.

- In the LIW method, the container is weighed using load cells. The weight loss of the container during emptying corresponds to the amount of powder transferred to the mixer.

- In the GIW method, the entire mixer is weighed and the increase in weight due to filling corresponds to the transferred weight.

If the user only wants to determine the quantity or weight of the material conveyed, two weight measurements before and after conveyance are sufficient. However, if the weight is to be used for control purposes to achieve a specified weight, continuous measurement at very short intervals is required.

There are numerous practical examples of both the LIW and GIW methods, and depending on the application and parameters involved, one method may be preferred over the other.

One advantage of the LIW method is that it provides integrated control of dosing and weighing within a single system, eliminating the need for data exchange with another machine across system boundaries.

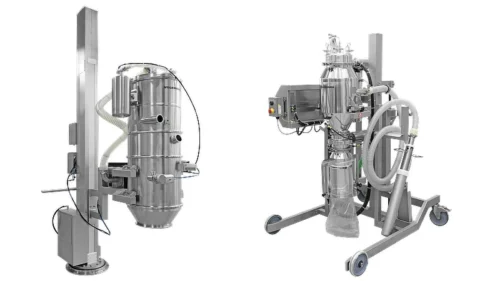

A system for a food producer: Conveying, weighing and dosing five components of a recipe, then feeding them into a mixer.

The PPC-type vacuum conveyor is mounted on a lifting column and has a rotary valve for dosing. The barrel, including its contents, is weighed on a floor scale and the rotary valve is controlled using the measured value.

A linear vibrating conveyor trough in XXL format is used for continuous product feeding with large conveying volumes.

The container has a weighing system and an integrated vibrating dosing unit.

Weighing during product feeding

For the sake of completeness, it should be noted that weighing can also be carried out at the product feeding station. For instance, the weight of the contents of a big bag can be determined at a big bag emptying station. Alternatively, the weight of the product can be determined in the hopper at a bag emptying station. However, weights determined at the product feeding station are not usually used to control conveying and dosing. The typical objective is to determine the weight or fill quantity in order to control the logistics of supplying the station with bulk material.

In a conveyor system, you can also combine weighing at the product feed point with weighing and dosing at the delivery point.