Advanced powder handling in additive manufacturing – vacuum conveying and more about 3D printing.

Finally another FORMNEXT in Frankfurt! We made good use of the long wait between exhibitions and presented our latest ideas and equipment for handling metal powders in pre- & post-processing of 3D printing.

There are various tasks in the area of powder handling for additive manufacturing: loading the machines with new powder, emptying the machines, recycling the powder through sieving and this also in combination with several printers from different manufacturers (multi-machine layouts). Very flexible powder handling systems are required, with vacuum conveying being the best transfer method for connecting processes. VOLKMANN not only presented this at its own stand at Formnext 2021, but also imparted its in-depth knowledge from almost 50 years of metal powder handling at various events and seminars around the trade fair.

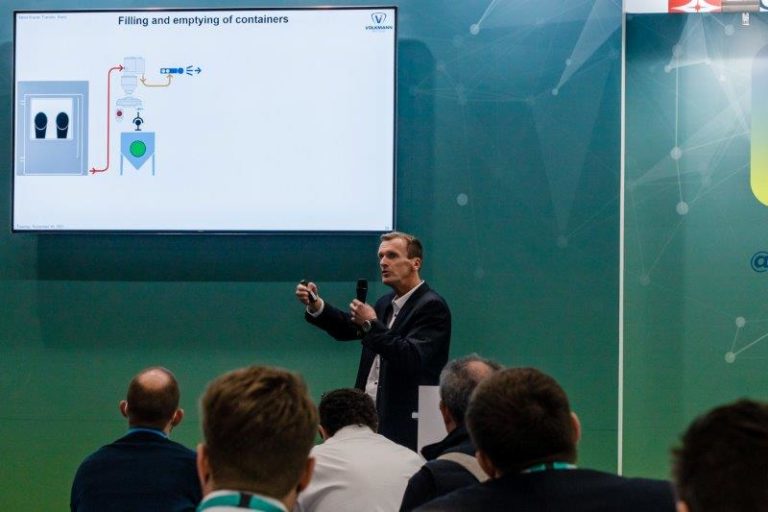

The presentation on the well-attended TCT Introducing Stage (Image 1) offered a comprehensive overview of the various applications in the AM industry. Starting with the basic concept of removing unprocessed powder from build jobs (Fig. 2) or unpacking stations, the presentation continued with an in-depth analysis of the material flow. For example, Figures 3 and 4 illustrate the importance of controlled and dust-free filling and emptying of larger containers, which is becoming more and more important when handling larger quantities of metal powder.

In addition, the following topics were dealt with both in the seminars and at the exhibition stand:

- Metal powder recovery and screening (PowTReX and other systems)

- Fully automatic emptying of build jobs at BMW and GKN (see below: IDAM research project)

- Reconditioning, drying, and mixing of scrap and virgin metal powders

- Split cone docking valve (VIAS) specifically for AM metal powder

- Customised engineering: e.g. safe powder handling for multi-machine layouts

Additional information:

Figure 5: Details of the IDAM research project “ ndustrialisation and Digitalisation of Additive Manufacturing”: www.ilt.fraunhofer.de/en/press/press-releases/press-release-2019/press-release-2019-4-17.html

You are welcome to contact us to find out about the latest advances in the various research and development projects.

Image index:

Photo 1 to 4: Dipl.-Ing. B.Eng.(Hons.) Thomas Ramme from Volkmann GmbH, Soest, reports on his more than 26 years of experience in vacuum conveying and metal powder handling.

Image 5: Insight into a fully functional de-powdering and reconditioning station that has already proven itself under real production conditions (IDAM).