Ideas And Solutions For The Pharmaceutical Industry

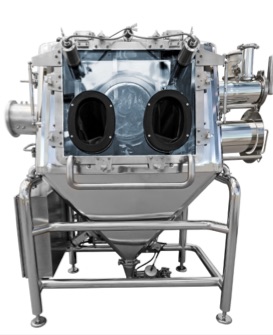

Vacuum conveyors comply to typical demands of the Pharmaceutical Industry (e.g. FDA, cGMP, WIP, CIP). They transport materials under vacuum sanitary and emission free. The systems are small in relation to the transfer rates achieved and highly flexible to install. Vacuum conveyors are the first choice for the transfer of powders in most pharmaceutical applications.

Vacuum conveyors and material handling solutions from Volkmann are used for feeding and transferring materials to and from processes like refilling bins, initial weighing, blending, screening, granulating, compacting and compressing. Mixtures can be conveyed free of segregation due to dense phase conveying, e.g. to feed materials into filling machines. The systems can be used for the transfer of capsules, dragees and tablets successfully, too.