Product Loading Stations

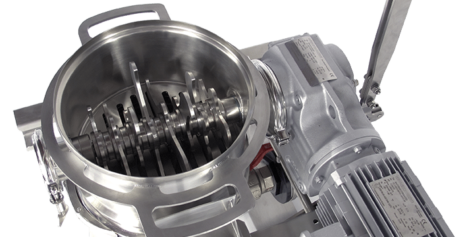

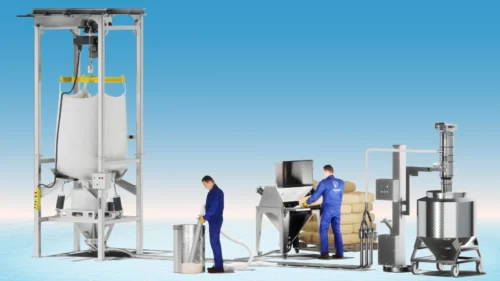

For emptying sacks, big bags, drums, containers or IBCs and other containers, and for feeding the powder, granulate or other bulk materials into a vacuum conveyor system, we offer appropriate product feeding stations. Efficient handling, safe and complete emptying of the container, trouble-free product entry into the conveying system and the avoidance of dust emissions are essential requirements for these stations.

Our loading stations, when combined with a conveying system, allows an easy and efficient addition of bulk materials into production processes.

Load products such as powders and granulated materials directly from barrels, drums, bags, special bins, and containers, even with plastic liners. Combine our units with process control systems which can integrate with remote controls and monitoring systems. All levels, alarms, and error messages, as well as other required information, can be transmitted for evaluation and monitoring.

Utilise our experience and knowledge and ask us for our solutions on how to pick up and convey the materials within your production process, for example for emptying bags and special bins, Big-Bags, Silos etc.

- Dust-free material handling

- Product aeration and loading with full control

- Avoid the difficult manual handling of all sorts of bulk materials packed in drums, sacks, and other containers

- Reduce health risks in the workplace

- Protect the environment from hazardous materials

- Increase the quality of your final products and the working environment