In additive manufacturing with metal powders, VOLKMANN is well established in the direct environment of 3D printers. What is less well known is that we are also active much earlier in the process chain. We also supply systems to metal powder manufacturers to fill the powders into bottles or transport containers.

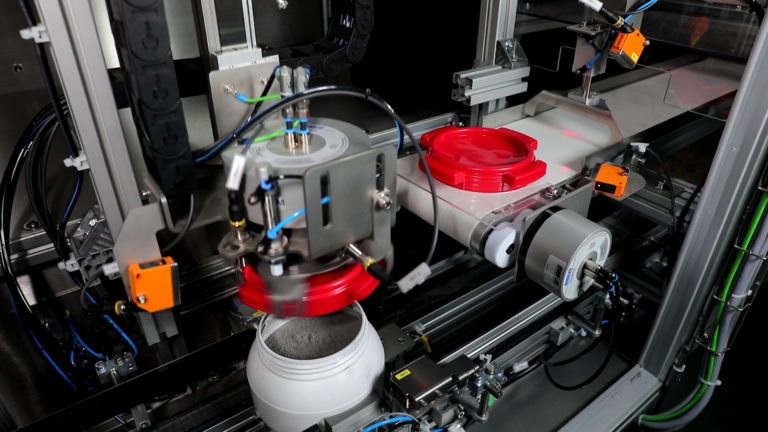

Our filling systems are designed according to the specific requirements and wishes of our customers. On the one hand, the various bottles and closures with their different sizes and shapes must be taken into account. But the filling process can also vary from customer to customer.

Some users want the bottle to be purged with an inert gas (e.g. argon) first in order to displace the air or reduce the oxygen content. The container is filled with powder while the bottle and its contents are continuously weighed. The tare weight is used to approximate the dosing of the powder to the target weight with narrow tolerances. Finally, the bottle is sealed with a lid.

Filling systems require safe handling of the powder and precise dosing of the specified weight into the bottle. As many metal powders are dust-explosive, the system must be explosion-proof in accordance with ATEX directives. We are recognised in the industry for our expertise in this area.

A video that we produced during test runs shortly before delivery provides a good insight into how these filling systems work.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information