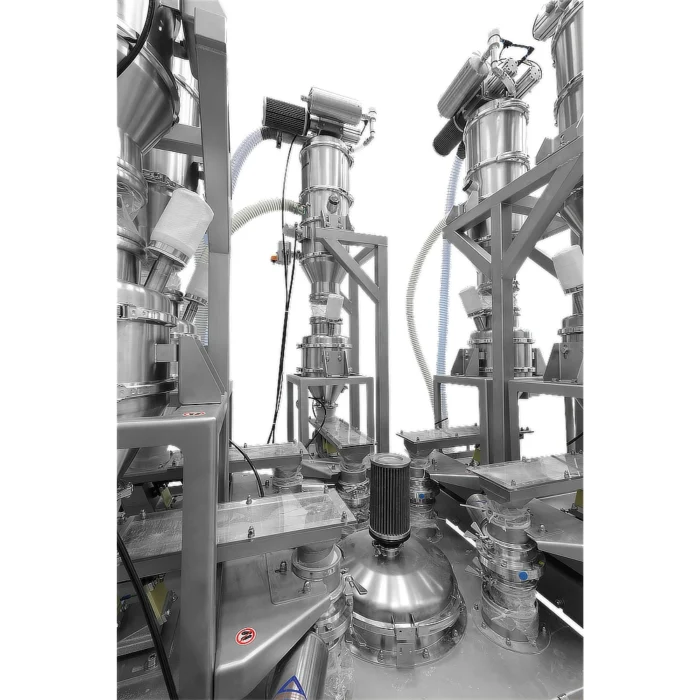

Dosing chute / Vibratory feeder

Continuous feeding of bulk materials, accurate to the gram. The VOLKMANN vibrating feeder can be used in a variety of ways and, in combination with a vacuum conveying system and a level indicator control, is ideal for the automation of feeding processes.

Depending on the application, the open vibrating chute or the closed hygienic dosing tube is recommended; both systems are easy to clean.

In combination with a vacuum conveyor and a material buffer, it is possible to implement various types of weighing. One example is negative weighing or dosing with a vibrating chute. Depending on the type of material, an accuracy of up to 1g per cycle can be achieved.

It is also possible to change a discontinuous feeding process into a continuous feeding process. And this at a capacity of up to 1000 kg/h.

You can find more information in our leaflet

Features:

- continuous material feed

- accuracy up to 1g (depending on product)

- effective and gentle operation

- easy cleaning

- can be used in EX areas

- low wear

- low noise

- surfaces in contact with product in stainless steel AISI 304 or AISI 316

Variants:

- vibration channel as open or closed U-profile

- vibration channel as closed tubular profile

- clamp connections at inlet and outlet

- length and width of the vibration trough to suit customer requirements

Optional:

- weighing modules

- dust-tight design

- can be combined with sieving

- quick-change sieve insert