Designed for multiple EOS metal additive manufacturing systems, end-to-end powder handling is now faster, safer, and automated for up to six printers

Krailling and Soest, Germany, 9. November 2023 – VOLKMANN and EOS today announced a scalable, closed-loop metal powder handling solution for users of the EOS M 290, EOS M 400 and EOS M 300 series additive manufacturing (AM) systems. Offered directly from EOS, the handling and processing of metal AM materials can now be managed through a holistic powder handling approach – for both pre- and post-processing – from initial powder preparation to a closed, fully-automatic powder circuit.

![closed powder loop – key visual (gray, 1600x900px) [DE] closed powder loop – key visual (gray, 1600x900px) [DE]](https://volkmann.info/wp-content/uploads/2023/11/geschlossener-Pulverkreislauf-2-1-e1711029055726.png)

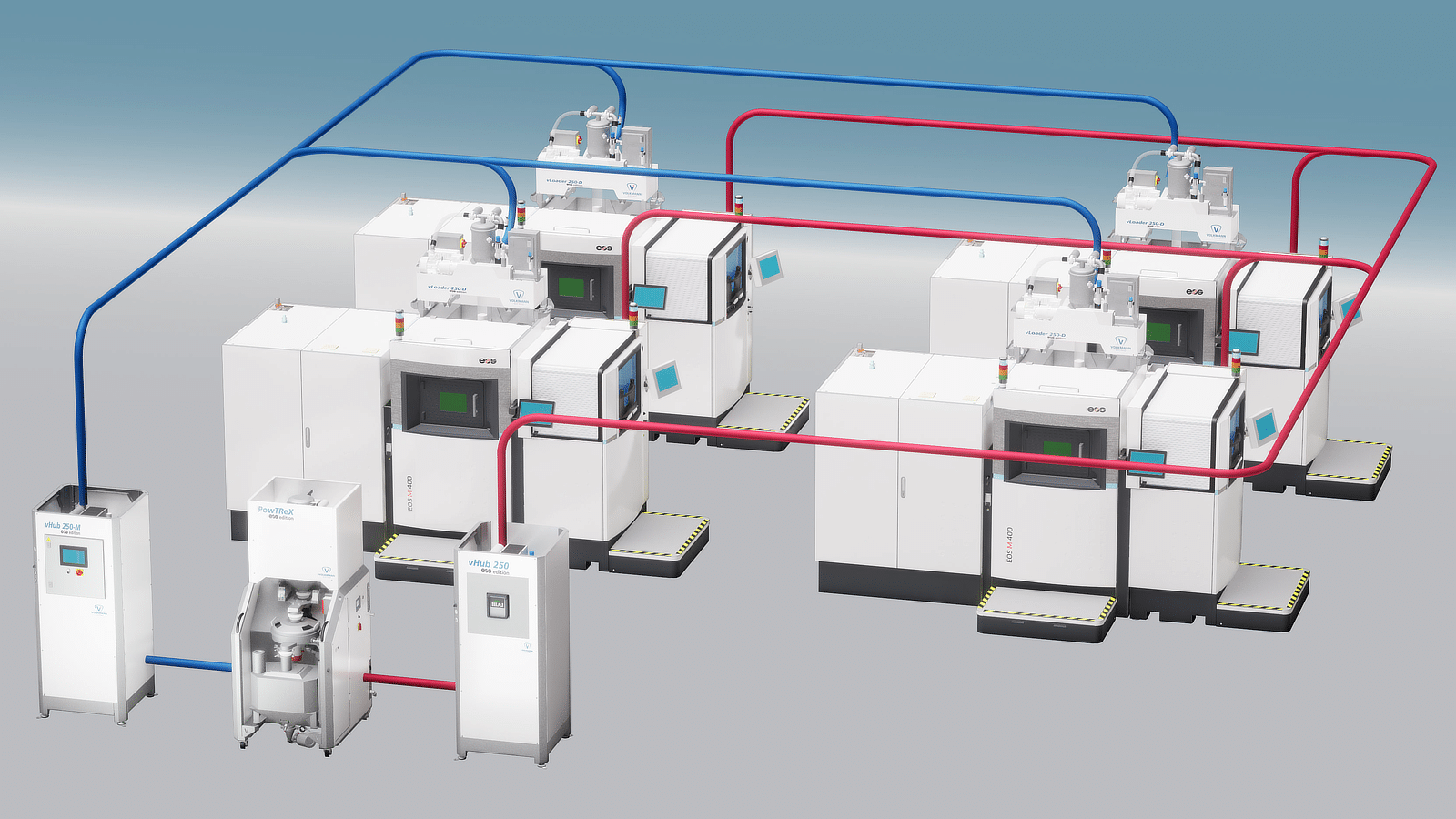

Closed powder circuits can be created with up to six (6) 3D printers in one production cell with fully automatic powder handling. The scaling of such systems can be done gradually, incorporating existing printers. The user benefits from this partnership through a holistic system for 3D printing and powder handling from a single source – from project planning to end-use application.

VOLKMANN has established itself in the AM industry as a leading provider of innovative systems for powder handling, bringing expertise to its partnership with EOS. Together, time-tested EOS technology was adapted, optimized and intensively tested so end users can now:

- Employ safe and clean powder handling in closed systems, providing better protection for operators against dust exposure, and at the same time better protection for the powder material against environmental influences and contamination

- Increase productivity and process reliability of the machines with fast de-powdering and automatic refilling of powder in parallel with the printing process

- Reduce manual work processes, with the possibility of a fully automatic powder handling in a 24/7 operation

- Leverage a high-performance central powder handling system that can supply up to six (6) EOS M 400 or EOS M 300 series AM systems in one (1) production cell

- Ensure powder quality through optional drying and closed process steps

- Have the flexibility of a scalable system that allows a production cell to expand incrementally and cost-effectively

In the modular concept, individual process steps are implemented by connecting several devices. These devices can also be operated individually, and, in the event of a later production expansion, can be connected to a fully automated system with up to six (6) connected AM systems. Between the devices, the metal powder is transported through pipes and hoses using the proven vacuum conveying system. A complete powder handling in a closed powder circuit includes the following process steps:

- Rapid extraction of metal powder from the installation chamber after printing

- Preparation of the used powder by sieving

- Optional intermediate buffering of the powder in a container before and after processing, as well as stockpiling for automatic filling of the printers

- Automatic filling of EOS M 400 or EOS M 300 series AM systems with powder

- Optionally vacuum drying of the powder directly before the printer is filled

End-users now have a single-point of contact for 3D printing and powder handling – from the initial project planning, through commissioning, for the entire life cycle of the system and for service, and will benefit from a complete, single-source powder material solution with the AM systems and the powder handling system which are optimally configured.

About Volkmann

VOLKMANN GmbH is one of the leading developers and manufacturers of systems for powder handling and material conveying. For more than 10 years, the innovative solutions for the processing of used powder and for the vacuum conveying of the powder have proven themselves in additive manufacturing with metal powders with numerous applications. This comprehensive know-how comes from numerous installations during the past 50 years for the chemical and pharmaceutical industry, for food, battery production and numerous other applications. VOLKMANN is a pioneer in the development of safe powder handling systems (ATEX) in dust-explosive environments.

About EOS

EOS provides responsible manufacturing solutions via industrial 3D printing technology to manufacturers around the world. Connecting high quality production efficiency with its pioneering innovation and sustainable practices, the independent company formed in 1989 will shape the future of manufacturing. Powered by its platform-driven digital value network of machines and a holistic portfolio of services, materials and processes, EOS is deeply committed to fulfilling its customers’ needs and acting responsibly for our planet.