who we are

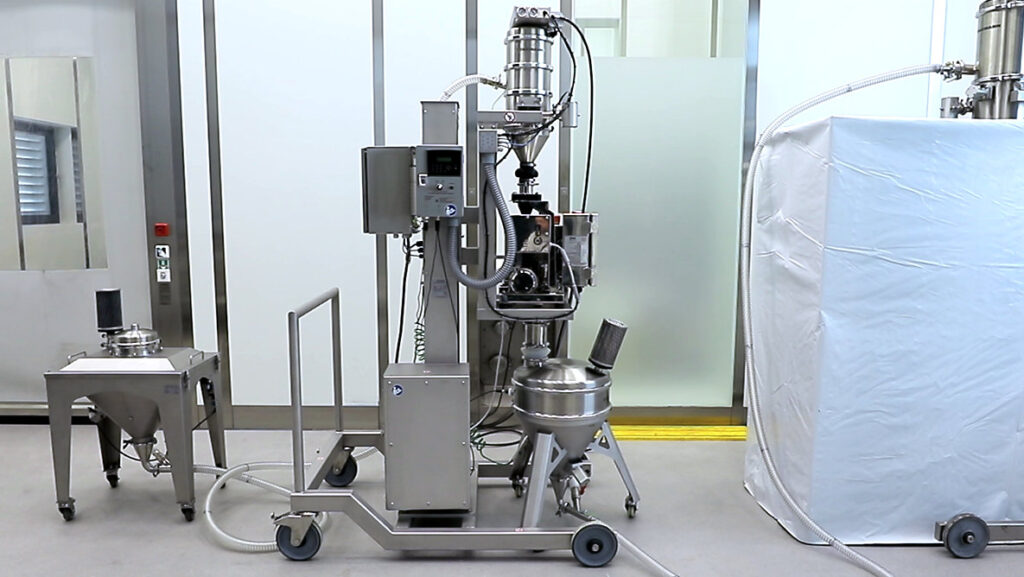

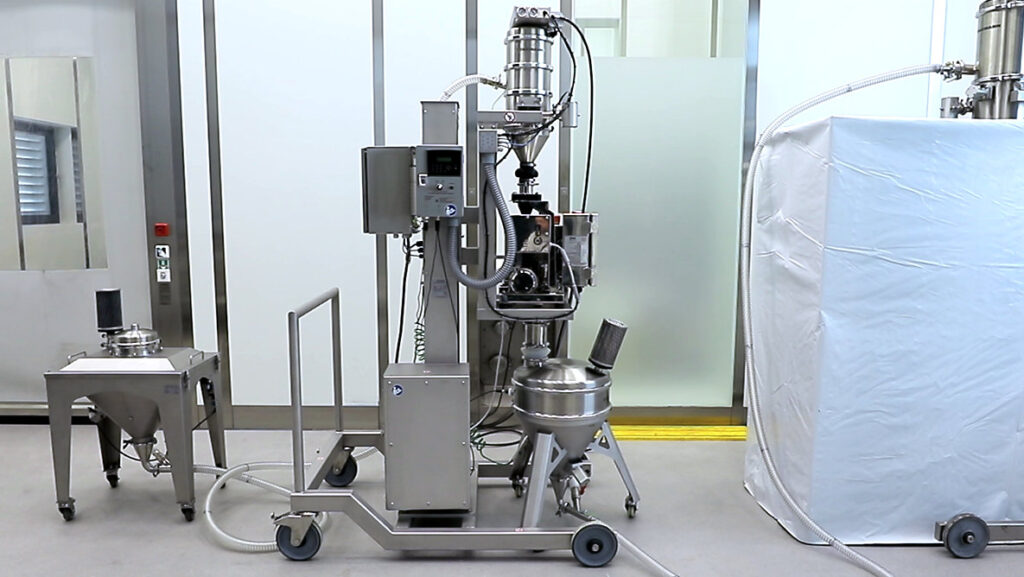

VOLKMANN supplies the optimum solution

Powder handling and material conveying – for powders, granulates and lumpy bulk materials – we can supply you with the optimum solution. And we also develop customised solutions and systems for our customers.

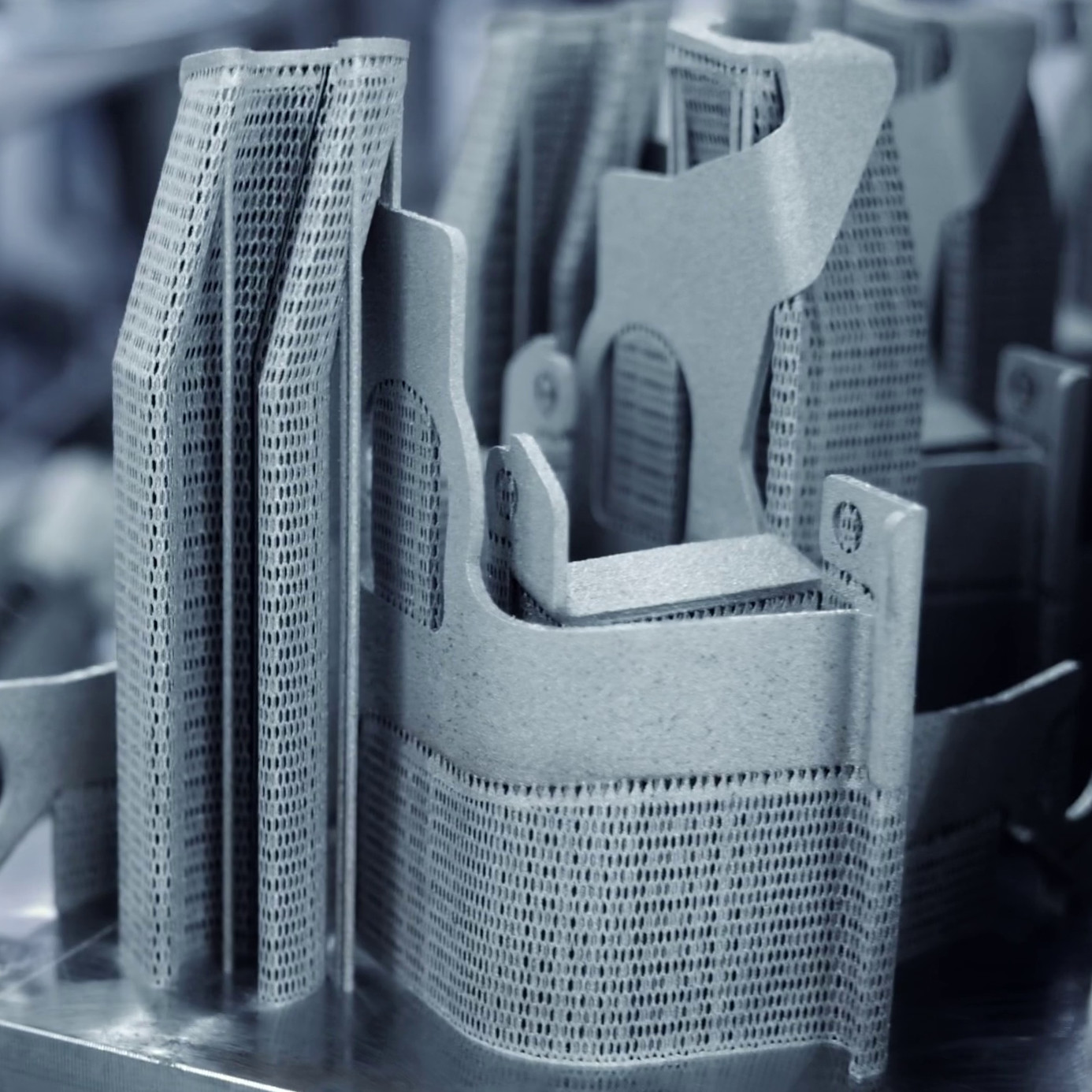

Numerous applications

Vacuum conveying systems are used for numerous applications or bulk materials: for food, pharmaceuticals, chemicals, metal powders and many more. In this section we offer you a general overview of the numerous possible applications. We also show some practical examples.

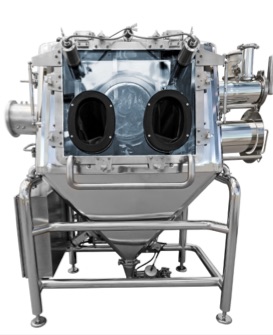

Our products and solutions

Our product programme includes a wide range of machines, devices and components for handling and conveying powder and bulk solids. We have put together a small selection for you here. You will find much more in the section about our products and solutions.

Visit us at the next trade fair, forum or conference!

Take the opportunity to talk to our experts about solutions to your questions and challenges in handling and conveying powders, granulates and bulk solids.

Seminars and training courses

We regularly organise seminars for our customers, or anyone else interested, in various fields around the topic of ‘safe handling of bulk products’.

News: