Newsroom

On this page you will find our news about the company, our products, the installations at our customers and much more.

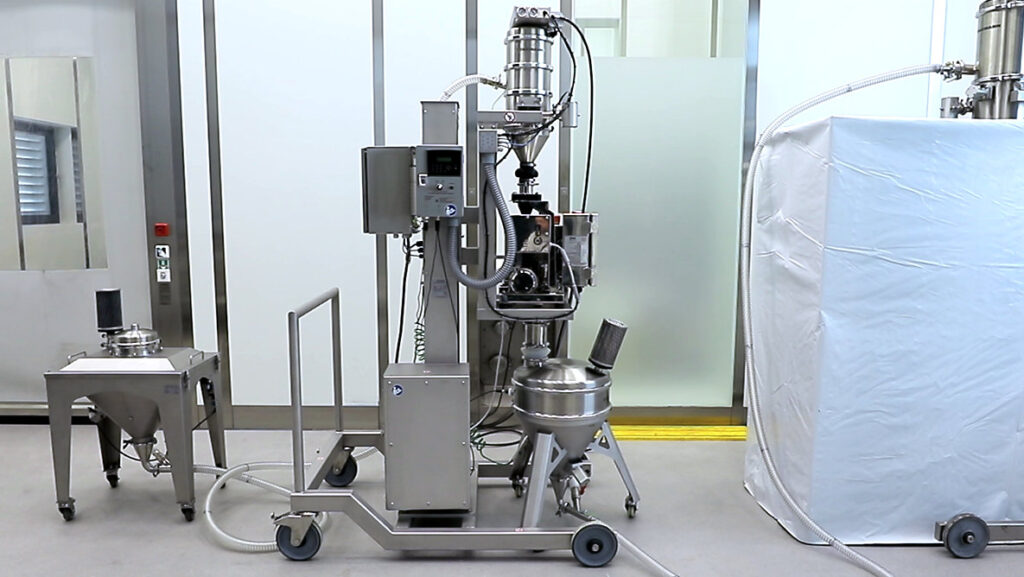

Vacuum conveying and metal detector combined

The combination of a vacuum conveyor and a metal detector on a mobile lifting column is the solution a customer was looking for to check

Visit by Minister Karl-Josef Laumann

Mr Karl-Josef Laumann, the minister for Labour, Health and Social Affairs for the State of North-Rhine Westphalia, came to witness the highly regarded apprenticeship style

Improved ergonomics thanks to adjustable secondary air

It’s often the details that make the difference. This is the case with our new PowTReX system suction lance for 3D printing. For the operator,

Emptying heavy drums – it’s so easy!

Up to 120 kg of raw material must be fed into the production system from drums. The station should also be suitable for bags and

The new production hall is growing in height

The construction of our new production hall is clearly taking shape. All the supports are in place, the roof beams have been installed and the

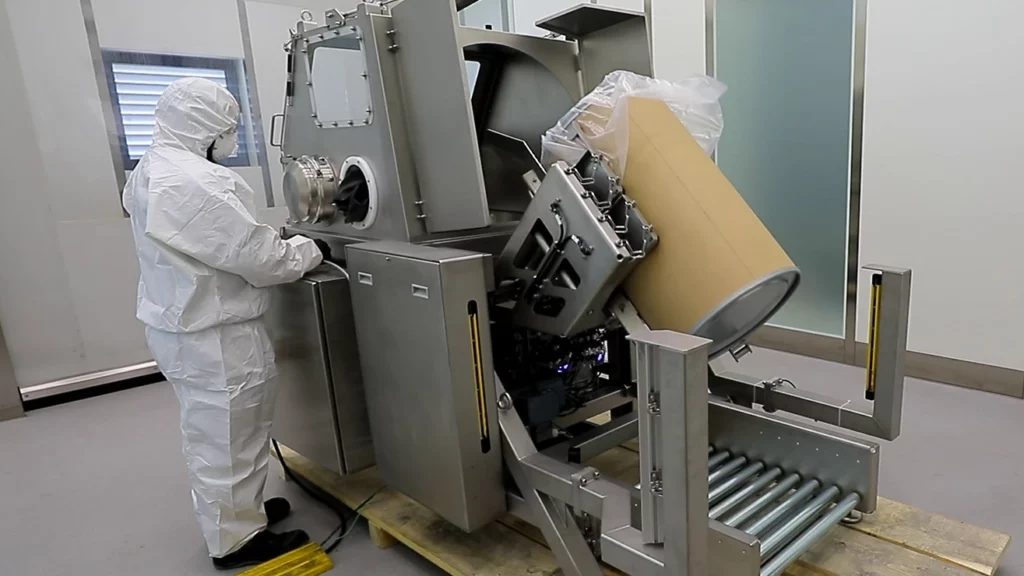

Filling machines for metal powder

We also manufacture filling machines for producers of metal powders. The operation of these machines is presented in a new video.

(Further messages will be loaded automatically when you reach the end of the page)