vHub 250 – metal powder buffer with integrated vacuum conveyor

The vHub is used in additive manufacturing in pre- and post-processing for buffering or intermediate storage of metal powder. With a volume of 250 liters (~8.8 ft³), the integrated powder hopper provides plenty of storage capacity: for holding powder from an upstream process, and for reliably supplying powder to a downstream process. Should this volume be insufficient, up to four vHub 250 units can be coupled to form an integrated compound. Thus, buffers with 500L, 750L and 1,000 liters (~ 17.6, 26.4, 35.3 ft³) volume can be realized.

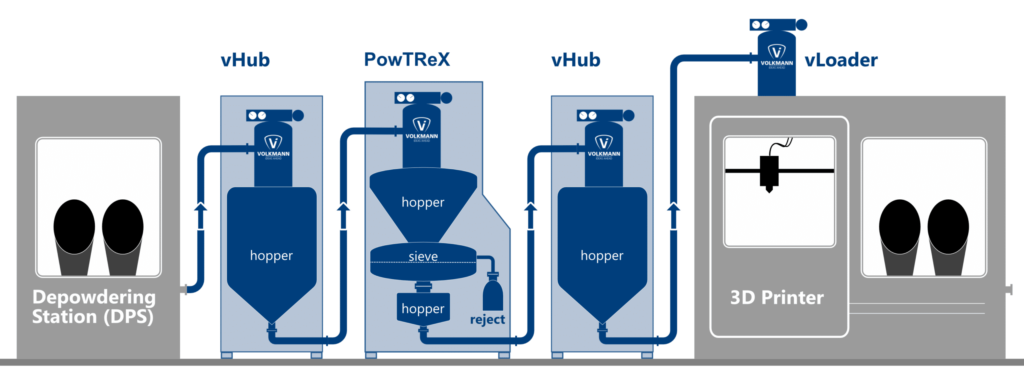

The integrated vacuum conveyor transports the metal powder from the feeding point, or the upstream equipment, into the vHub 250. In this way, for example, powder can be conveyed from a 3D printer, a powder reprocessing station (e.g. PowTReX) or from a container over a distance of up to 25 meters. Positioned in the direct vicinity of a 3D printer, the print job can also be manually unpacked by means of its hose and suction lance.

One area of application is the rapid emptying of even large build volumes in an uninterrupted process. This is made possible by the high conveying capacity (e.g. stainless steel powder up to 1,500 kg/h (3340 lbs/hr.) in combination with the large storage capacity. As a result the 3D printer quickly becomes available for new print jobs and the productivity of the plant is improved.

The vHub 250 is commonly used for the following tasks:

as a buffer reservoir for excess build metal powder, positioned between the 3D printer and the powder reprocessing system

as a supply reservoir for fresh or reprocessed metal powder to supply 3D printers

Typical arrangements are:

- 1 x 1: The vHub 250 obtains powder from an upstream device and makes it available for a downstream device or process.

Example 1: 3D printer ⇒ vHub 250 ⇒ Powtrex

Example 2: PowTReX ⇒ vHub 250 ⇒ vLoader 250 + 3D printer - 6 x 1: The powder is fed and collected from up to six 3D printers, unpacking stations or other systems. The vHub 250 forwards the powder to a downstream device, e.g. a PowTReX.

- 1 x 6: With this variant, the vHub 250 serves as a central powder reservoir for the supply of up to six connected 3D printers. The vHub 250 is supplied with reprocessed powder via an upstream PowTReX. A docking station (e.g. vDock) for feeding metal powder from IBC containers can also be used.

A closed powder loop in a multi-machine setup can be realized, for example, with a PowTReX and two vHub 250’s. The first vHub receives used powder from the connected 3D printers and buffers it. The powder is successively dispensed to a PowTReX, and the reprocessed powder is subsequently stored in the second vHub 250. From there, the 3D printers are supplied with metal powder.

A closed powder loop in a multi-machine setup can be realized, for example, with a Powtrex and two vHub 250’s. The first vHub receives used powder from the connected 3D printers and buffers it. The powder is successively dispensed to a Powtrex, and the reprocessed powder is subsequently stored in the second vHub 250. From there, the 3D printers are supplied with metal powder.

Features of the vHub 250:

- can be used for all metal powders commonly used in Metal AM

- ATEX certified: also suitable for dust explosive metal powders

- material in contact with product: Stainless steel (316L), glass bead blasted surface. Ra ~ 1.1 µm, wall thickness: 1,5mm

- optional: inert gas operation (circuit gas operation)

- integrated vacuum conveyor:

- sucks up to 1.500 kg (3340 lbs) metal powder per hour

- integrated double filter stage to protect employees and the environment

- optional: level-controlled suction via sensor in the upstream powder supply system

- optional: remote control for the suction process, with status LED

- integrated buffer tank:

- volume 250L (8.83 ft³)

- volume up to 1000 L (35.3 ft³) by combination of up to four vHub 250

- including min. / max. sensor

- optional: weighing of the container

- incl. discharge aids

- feeding pipe bend NW 32 (1 ¼”) for connection to the downstream process

- easy and quick to disassemble and cleaning without tools

- Unitronics PLC with 2-line display and membrane keypad

- required footprint of less than 1 m² (11.1 ft²)